| Next Chapter | Previous Chapter | |

| Chapter 14: What Happened to the Dairy Business | Contents | Chapter 12: Mowing Grass |

My father, Paul Bond, was a horse for work. He was six feet tall and very strongly built, with excellent coordination. Unlike some modern athletes, he continued to play ball and exert himself long after college.

When he was at Salem, Grandfather T. M. Bond was in the sand, gravel and concrete business, all of which came in railroad cars. (We don't have commercial deposits of them here in the Central Appalachian Plateau.) It was considered a day's work for a man to unload a railroad car of sand, the philosophy being that if you paid for such work by the hour, it was easy for the man not to make a good effort. Dad gloried in finishing his day's work in mid-afternoon.

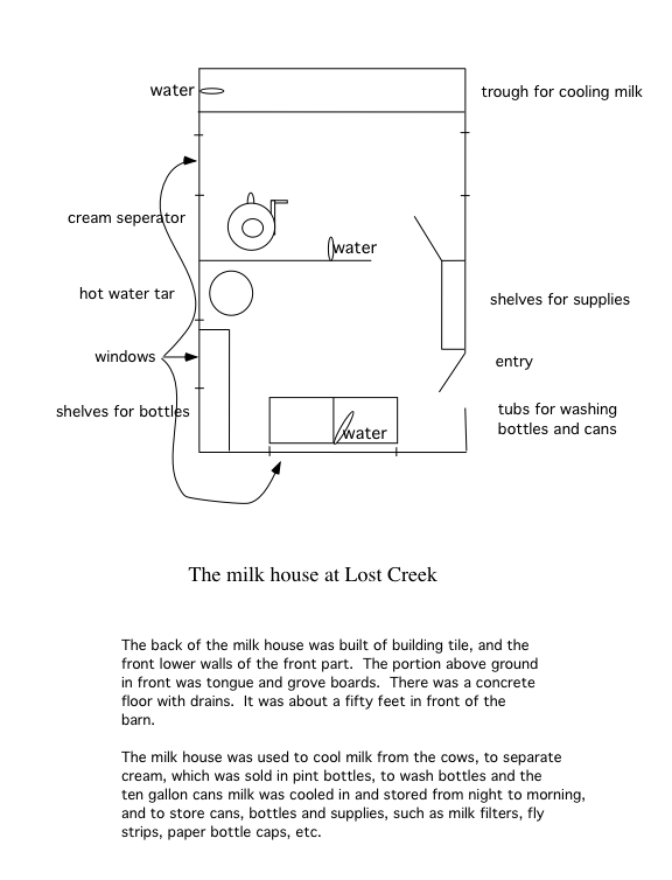

My father liked chickens and sheep, but milk production was the mainstay of the farm. Below the barn was a milkhouse shown on the next page. In the front was the wash room, where every bottle had to be washed, and filled. There were a sink and a large, rather high table. A hot water tank was in the corner opposite the door.

The door to the back room, which served as a cooler, was near the outside door. Dad would carry buckets of milk down from the barn and put them into 10 gallon cans. Then the cans would be set in the trough in the back of the room, which was full of water. There was no mechanical cooling in those days. The cooling effect (fresh milk is the body temperature of the cow, a few degrees above the body

(Illustration 13-1)

temperature of humans) was provided by well water. The temperature of well water is the long term average of surface temperature in any location, about 44 Fahrenheit degrees in Central West Virginia. This is four degrees above the average temperature of a modern refrigerator.

Mom did much of the washing of bottles, which was about as arduous a job as the milking. Aunt Lotta washed some in the summer time when school was not in session and Dad had more work to do, and Mom had the garden and canning in addition to child care. Dad did a lot of bottle and can washing, too, in the winter especially.

Dad bragged that people in West Milford, where he sold milk, said they could set their clocks by the fact that he always "hit the bridge" across the West Fork at 6:00 AM (they could hear the rattling boards).

During the depression of the thirties no one had money, but if you had something to sell that people needed, it wasn't as bad as if you had nothing to bring money in but your labor or some product that people could do without. Milk was needed. Dad often let men work off their milk bill, when they had no money, and lost a good bit in unpaid bills, too. In later years Dad would say he had a "half interest in half of the kids in Milford," because of the milk that fed them in the depression.

The horrible thing about a dairy is that you have to milk the cows morning and night, and do the "work" between. The standard joke was that milking was "just chores." This makes for a short night under the best of circumstances. Dad was into "Independent Team" basketball. This consisted of adult men who played basketball all over the country - places like Sardis, Lumberport, etc. The hard road came out to

(Illustration 13-2)

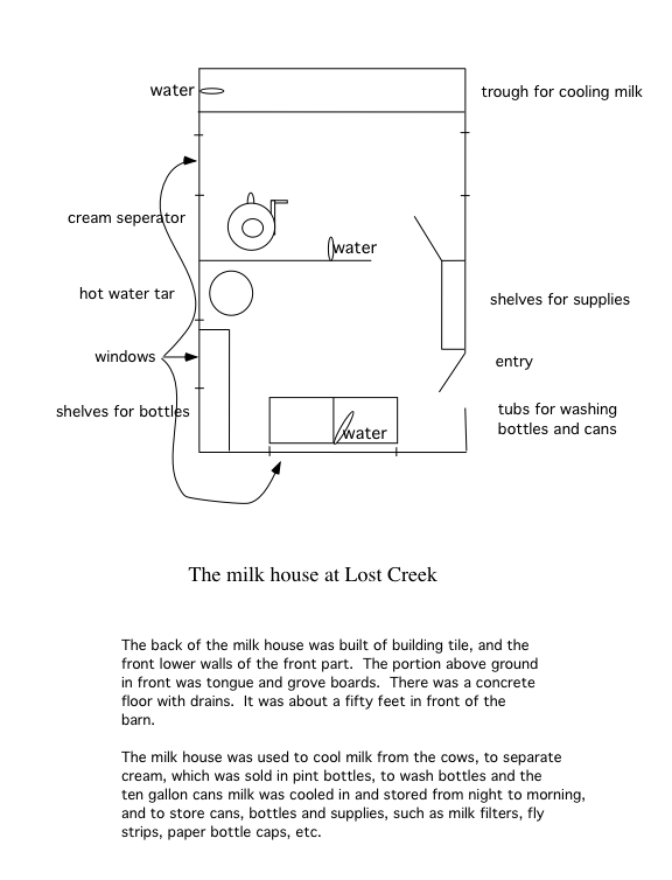

This cream separator is like the one Dad used to separate cream from milk when he ran the dairy. Whole milk was poured in the upper bowl, the crank started and the valve opened. The upper outlet sent cream into a container setting on the brown tray and the lower one sent skimmed milk into a large can setting on the floor on the side opposite the crank.

On the tray is a strainer, which was used on a milk can beforethe seperaton process. Buckets of milk directly from the cow were poured into the strainer, where it passed through a disposable fiber pad and into the can. - Thanks to Watters Smith State Park for the opportunity to take this photo.

Sycamore Dell, now the intersection of Sycamore and U. S. 19. They would travel to the location of the game, play and return the same night. Dad always got up at 3:00 AM to do the milking. Some nights were almost non-existent. He courted mother while running the dairy, too, but wasn't playing ball by that time.

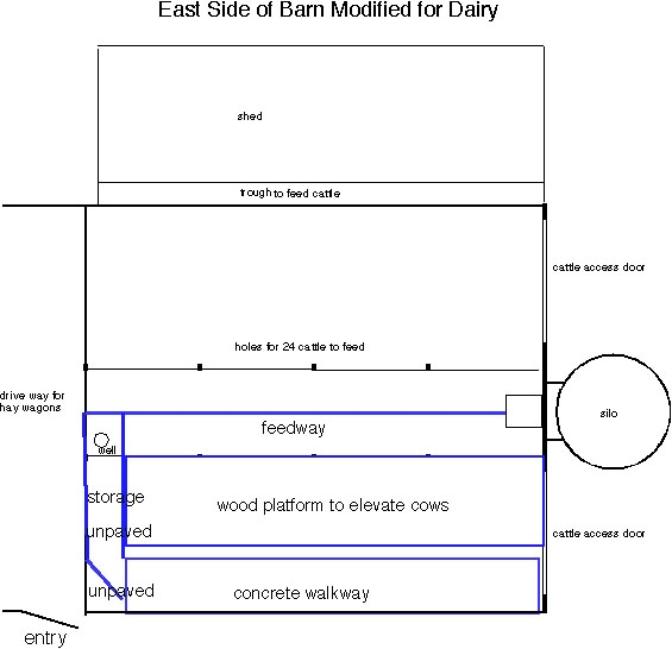

Twenty cows must have been the limit, judging from the size allowed for the dairy in the lower side of the barn. The principal feed in the winter was hay and corn silage grown on the farm, and in the summer it was pasture. Some grain was purchased at the West End Feed Store. I remember riding along to pick it up.

The story about the farmer squirting milk directly into the cat's mouth from the cow's teat is true. I saw it happen many times. Same goes for little kids - I was frequently the beneficiary, as were my sisters. Funny, they can't remember it now, though.

The cow's heads were caught in stanchions, boards arranged to keep them in place. Each cow had her place and knew it. Each cow had a name. I won't argue they knew their names, but many people in the dairy business thought cows recognized their names. They came in voluntarily, because they got to eat. They stood on a wooden platform about six inches high, long enough to receive the cows rear feet, short enough so most of the manure went off the platform.

Behind the cows was a gutter some foot or more wide, and behind that a concrete platform four inches high and about four feet wide. Both cows and people walked on this concrete platform. Cows crossed to the wooden platform to enter the stanchions, and the people to milk the cows. The gutter had to be cleaned each time the cows were let out. Tons and tons of manure accumulated during the winter outside the door where the cows entered, and had to be hauled away in the spring, but it was the principal fertilizer. You could lay a wide board on the pile and run the wheelbarrow up it. When the dairy ended there was a pile that stood near the silo for years before it was removed.

(Illustration 13-3)

One of Dad's Ayrshire heifers

Flies were always a problem in warm weather. There were sticky strips about an inch and a half to two inches wide, coiled up in a cardboard tube to catch them. You pulled off the cap, which pulled out the center of the coil and extended it for about three feet. I remember the sticky brown surface of the translucent material. The cap also had a loop, so the "fly paper" could be hung up. There would also be spray to put on each cow when they came in to milk, diluted with diesel oil (judging from the smell, which I now recognize well).

There were a lot of smells in the process. The smell of the manure (which changes with what the cattle eat and is characteristic of their diet - pasture, silage, grain, hay), the characteristic odor of the cows themselves, which is probably their sebum, the fat exuded to keep the skin soft and pliable, the urine,

(Illustration 13-4)

the milk, their food, the dry moldy smell of the empty barn, the dust (mostly dry manure and feed particles, and human sweat, the milk itself, hay stored overhead, and so on). This all in a place which is kept reasonably clean.

Smell, you know, is quite different from sight and sound. Smell is older in an evolutionary sense than sight or hearing and the sensory organs are directly connected to the base of the brain. Sight and sound pass from the retina of the eye and the cochlea of the ear, through several organizing areas of the brain before the signal reaches the inner, very old, part of the brain which controls emotions and reactions. You can close your eyes and see your house in your mind, you can relax and hear you favorite music or your child's voice in your mind. But try as you will, you cannot summon up even the most familiar odor. And you can remember smells from childhood even if you have not smelled them for years. The associations are essentially never forgotten as sights and sounds are.

When I was in the army, four of us were chosen to go to Fort McClellan to the Chemical Corps School. One of us was a Greek-American fellow from Brooklyn. When we got off the train at Anniston, Alabama, he said, "What IS that smell? " I haven't smelled that since I was a boy in Greece." Then, "Pig Shit!" We all laughed, of course.

We tend to think of barn odors as offensive in our time. But in rural America of a half a century or more ago the odors of the barn were warm, familiar, and pleasant. They meant a reliable source of milk, cheese, cream, butter, pork, chicken and beef. The cow is a wonderful animal which can change grass, which grows everywhere there is sufficient rain and it is not crowded out by forest, into rich food, high in the nutrients which are frequently deficient in plant-derived food. It takes a special technology to keep animals, but it produces very rich food with much less work than plants. And it can be done in areas that are not suitable for row crops, due to lack of water or steep hills.

Aside Cattle business

Growing ruminant livestock, such as beef cattle, is usually conducted on land that is not well suited for other crops. The cattle consume grass which is abundant in some places, and is not suitable for human food. In the West, the land used is too arid. Here in Appalachia the land is too steep and fields are too small and irregular in shape to cultivate with large equipment. In some places, like the South, cattle are grown where the soil is too wet for more profitable crops.

In other places cattle frequently consume waste from other crops. We humans eat seeds of cereal grains, corn, soybeans, peanuts, etc. and the oils pressed out of some seeds. The residue can be fed to cattle. The large amount of residue from making ethanol from grain, either for beverage use or fuel, is also fed to cattle. The use of un- (or minimally) processed grain is a relatively recent historical development and will doubtless disappear as soon as the grain and it's residue becomes more profitable for some other use.

The ancestors of the cattle we use, Bos taurus, were domesticated about 8000 or 9000 years ago in the Near East. Some believe the reason they were domesticated is because they could survive the winter on straw left after cereal grain harvest. Our present domestic livestock is derived from strains that were developed in Europe by the farmers who migrated North and West from where the animals were first domesticated. In the United States South and Southwest there is some influence from cattle imported from India,Bos taurus indicus. They are used for crossbreeding to convey heat and insect resistance and to gain hybrid vigor.

Most forms of wealth can be stolen, but livestock are unique in that they can walk off by their own volition. Good fences are important for maintaining control. Casual theft, called paddywhacking in Australia, is common. Cattle get out and are sold by the neighbors in whose field the cattle come to rest, even when they are marked. (Cattle are not inclined to roam alone when they can join other cattle.) Rustling, which is deliberate theft, is less common, but occurs. Some years ago the principal rustler in this area was claimed by some to be the sheriff of an adjoining county who had a remote farm. Cattle sale barns are not very concerned with the source of animals. Most stolen goods must be sold through a "fence" who pays only a fraction of the item's worth. Stolen cattle usually bring their full worth.

There is a proposed national cattle identification system, in which every sale of an animal must be reported to a central records agency. It is designed to track back in case of illness to all previous owners, to help prevent spread of the disease. This may also have an inhibiting effect on theft. Such a system is in use in Europe already.

In addition to meat and milk, which are produced by different breeds that have the same ancestor, cattle produce hides for leather, bones for bone meal (used as fertilizer), gelatin, manure for fertilizer and compounds extracted from some glands.

Many persons of other than European ancestry lack the enzymes to digest milk when they are adults, because cattle have not been used for milk where their ancestors lived. The Chinese are particularly averse to milk and milk products.

Other "animal industry," such as chickens and hogs are "integrated." In the chicken industry baby chicks and feed are provided by a corporation, which buys them when grown. The farmer provides buildings and labor and disposes of the dead animals and manure. He has to follow specifications, and is assured of a market. Many hog farmers are assured of a market when they follow the buyer's specifications. So far cattle breeding has not come to this pass for most of the industry, in part due to the huge capital requirements in land and low profit for the beef calf producer.

A few companies have been able to "brand" beef, however. For calf producers they specify breeding stock origins, vaccinations, time of delivery, etc, to gain a very standard product to the feed lot and on through to the "harvest." The product is "branded" by selling it in a wrapper with a company name at a higher price. "Commodity" beef, without a company name, is still more common in stores today, however.

| Next Chapter | Previous Chapter | |

| Chapter 14: What Happened to the Dairy Business | Contents | Chapter 12: Mowing Grass |

Copyright © 1998, 2006, 2008, 2011 S. Tom Bond (stombond at hughes.net)